CHINA HUANENG is one of the leading companies in China’s energy industry. It is committed to the development and utilization of clean energy and has made important contributions to national energy security and green development. It is a great honor for SCU to cooperate with CHINA HUANENG to provide an automated centralized charging container system for the 2MW supercharging station heavy-duty trucks power swap project it invested in, providing key support for the mine’s new energy heavy-duty trucks to achieve efficient and high-power charging and power swapping.

Electric heavy-duty trucks supercharging station

The mine is an important production base in Xinjiang and uses a large number of heavy-duty trucks during operations. To promote the replacement of electric heavy-duty trucks and the construction of battery replacement stations across the country, all operating vehicles in the mining area use electric heavy-duty trucks. Electric heavy-duty trucks are less noisy, require less maintenance and produce fewer emissions than traditional vehicles, helping to protect the environment.

However, the working location of electric trucks is usually far away from charging facilities. To save time and cost and improve efficiency, this project built a 2MW supercharging station. The charging current of the pantograph charger can reach 1000A, which greatly increases the charging rate, saves charging time and improves operational efficiency.

Solution

40ft container system

The system supports direct access to an AC 10kV power supply and consists of an energy storage bidirectional converter PCS, an energy management system EMS, an intelligent charging set, a dry-type transformer, a heptafluoropropane fire protection system, and a temperature control system. Its internal PCS system works closely with the charging system, and the energy management system (EMS) accurately controls the one-to-one docking of the batteries loaded on the flatbed truck to complete charging.

The total power of PCS is 2625KW (5*525KW), which converts AC into DC to power the pantograph charger. The PCS system is equipped with both hardware fault protection and software protection. The protection functions are complete, the protection scope overlaps and there is no dead zone to ensure system safety under various fault conditions.

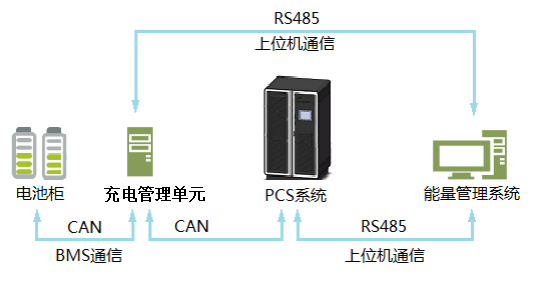

The PCS system provides a CAN interface with the charging management unit, uses the PCS system internal communication protocol to communicate with the charging management unit, and the charging management unit communicates with the BMS battery management system. Intelligent charging management of the battery is realized through PCS and charging management unit→BMS.

The PCS series modular energy storage converter is a new modular energy storage converter system that combines the advantages of digital technology and new semiconductor technology. The PCM energy storage converter module used in the system has the characteristics of extremely high power density, reliability, efficiency, intelligence and flexibility.

New energy heavy-duty truck battery replacement

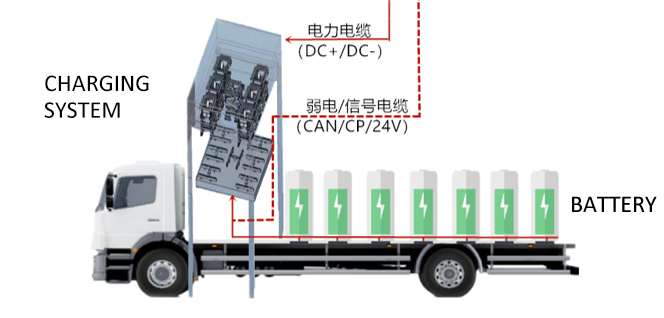

Electric truck charging adopts the battery swap mode. The electric truck transports the batteries to a high-power charging station via a flatbed truck, uses the charging station to charge, and waits for the battery to be fully charged before transporting it back to the battery swap station.

In the battery swap mode, the electric card does not need to wait long to be charged, which effectively solves the problem of cruising range and improves work efficiency. The charging set adopts automatic positioning technology and is divided into two parts: the charging device and the power-receiving device. The charging device is installed above the parking position of the vehicle, and the power-receiving device is installed at the rear of the battery trailer. Once the pantograph charger is in place, the retractable charging device can automatically dock with the charging device to achieve automatic charging. SCU will continue to work with partners to contribute more to the development of the new energy transportation industry.

Green charging, environmental protection first

SCU container systems bring multiple benefits. First of all, it enables fast and convenient charging of engineering vehicles far away from charging stations, improving work efficiency. Secondly, it adopts a green charging solution, which reduces dependence on traditional fuel, reduces carbon emissions, and helps mines achieve green transformation. At the same time, this solution also demonstrates CHINA HUANENG’s positive actions in the fields of sustainable development and environmental protection and establishes a good corporate image.

The cooperation between SCU and CHINA HUANENG is not only a successful project implementation but also an active exploration to jointly promote the development of green energy and green transformation. In the future, both parties will continue to work together to deepen cooperation, work together to build a cleaner, more efficient and sustainable energy system, and make greater contributions to promoting green and low-carbon transportation!