The Netherlands is the fifth largest milk producer. In the Netherlands, 98% of the milk is processed into cheese, milk powder, butter, and other dairy products.

Our client is a milk powder factory. The major energy users in the milk powder factory include pasteurization, spray drying, homogenizers, heating/boiling, compressors and centrifugal separators.

Sustainable food production and processing is a topic of increasing importance globally, and the introduction of sustainable agricultural practices and renewable energy into dairy processing is of great significance and increasingly important in a world with limited carbon emissions and resources.

In order to save electricity, the milk powder factory installed photovoltaics. Since photovoltaic power generation cannot store energy and sell it to the power grid for profit, the customer hopes to store the excess energy generated by photovoltaic power generation in the battery and use mains power to recharge the battery in the afternoon when electricity prices are low.

SCU provides commercial and industrial energy storage solution for Dutch milk powder processing plants. By combining the self-consumption of photovoltaics and clever application of the EMS system, this milk powder factory has not only improved economic efficiency but also injected new impetus into sustainable development.

Solution:

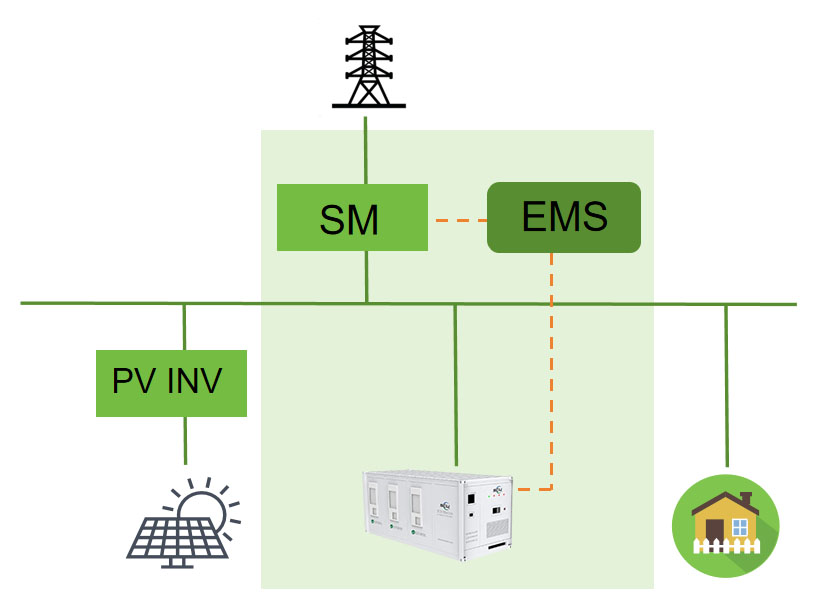

Based on the load capacity of the milk powder factory provided by the customer and combined with the local power grid price, we provided the customer with a set of commercial and industrial energy storage solutions. We selected a 20ft energy storage container, a battery capacity of 1MWH, a PCS power of 400KW, an AC coupling solution, combined with EMS, and control Charging and discharging time can not only save electricity bills but even obtain negative electricity prices.

Advantage:

- Profit from negative electricity prices:

The application of SCU energy storage containers is not limited to energy storage. The customer intelligently sets the charging and discharging time of the energy storage container through the energy management system (EMS), taking full advantage of the local negative electricity price policy in the Netherlands. During different periods of time when electricity prices fluctuate, the system automatically adjusts charging and discharging strategies and cleverly utilizes peak and valley electricity price differences to achieve intelligent electricity use, thereby achieving considerable savings in energy costs.

- Improve self-sufficiency:

This energy storage option provides customers with more self-sufficient energy, especially with photovoltaic systems. The milk powder processing plant uses photovoltaics for its own use and stores excess energy in SCU’s energy storage containers. This self-sufficiency model not only provides businesses with a source of renewable energy but also helps reduce reliance on the traditional grid.

- Supporters of sustainable development:

This SCU energy storage solution not only provides economic benefits to enterprises but also contributes to their sustainable development. By maximizing the use of its photovoltaic system and SCU energy storage containers, the milk powder processing plant is at the forefront of the industry in energy management. This sustainable energy utilization method has a significant positive impact on reducing carbon footprint and achieving green production.

SCU will continue to be committed to providing efficient and sustainable C&I energy storage system solution and jointly creating a clean and smart energy future.